Team:Charlottesville RS/Project/Applications

From 2014hs.igem.org

Ingamename (Talk | contribs) (→Moores Creek Wastewater Treatement Plant) |

Ingamename (Talk | contribs) (→) |

||

| Line 430: | Line 430: | ||

=== === | === === | ||

| - | [[image:denitrification.png|thumb| | + | [[image:denitrification.png|thumb|400px|center]] |

==Sequencing Batch Reactor== | ==Sequencing Batch Reactor== | ||

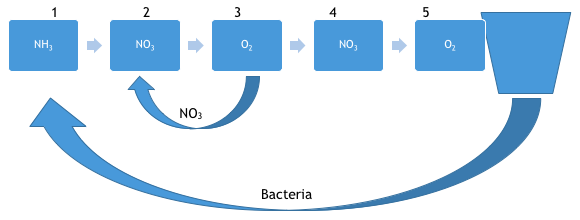

Since we do not have as much space as the Moores Creek Wastewater Treatment Plant, so we used a sequencing batch reactor, where instead of the water flowing from step to step, the water remains in the same location and aerators are turned on and off to alternate between aerobic and anaerobic zones. Instead of just two aerobic and anaerobic zones, we used sixteen. | Since we do not have as much space as the Moores Creek Wastewater Treatment Plant, so we used a sequencing batch reactor, where instead of the water flowing from step to step, the water remains in the same location and aerators are turned on and off to alternate between aerobic and anaerobic zones. Instead of just two aerobic and anaerobic zones, we used sixteen. | ||

Revision as of 14:43, 20 June 2014

Moores Creek Wastewater Treatement Plant

The Moores Creek Wastewater Treatment Plant (WWTP) is managed by the Rivanna Water & Sewer Authority. The purpose of the water treatment plant is to use bacteria to purify waste water so it can be released into Moores Creek. Bacteria are used to process the waste and purify the water. However, these bacteria require nourishment, so every year the plant purchases $250,000 worth of glycerine in order to feed these bacteria. Our idea is to use genetically modified E. coli to produce a bioplastic called PHB, which the bacteria that purify the waste water could consume for energy, and thus save the city up to $250,000 on the Moores Creek WWTP and potentially apply to other WWTPs as well.

How Wastewater Treatment Plants Work1) Anoxic: Polyphosphate-accumulating organism (PAO’s) are able consume simple carbon compounds without the presence of an external electron acceptor, such as NO3 and O2. The bacteria in this step are deprived of NO3 and O2 to give the PAO’s a competitive advantage. This is done to enhance the removal of phosphorus.

|

Sequencing Batch ReactorSince we do not have as much space as the Moores Creek Wastewater Treatment Plant, so we used a sequencing batch reactor, where instead of the water flowing from step to step, the water remains in the same location and aerators are turned on and off to alternate between aerobic and anaerobic zones. Instead of just two aerobic and anaerobic zones, we used sixteen. |

"

"